Time-Sert Thread Repair Insert

Features and Benefits

A TIME-SERT is a solid-body thread insert offered by Time Fastener Company. Some of the features that make TIME-SERT a good choice for many stripped or damaged thread repair applications include...

- Solid bushing insert

This simplifies installation and produces a strong, permanent repair by allowing the full torque of the fastener to be applied to the repaired threads. - Self-locating capability

The insert is provided with a built-in flange that automatically positions its depth during installation. - Thin-wall design

The thin wall is made possible because the internal and external threads of the insert are synchronized. The small outer diameter of the insert allows for installation in locations where space is a premium. - Self-locking design

The lower internal threads of the insert expand during installation to mechanically lock the insert in place.

- The insert flange contacts the workpiece surface and prevents it from winding its way into the prepared hole during installation.

- Synchronized internal and external threads allow for a compact insert profile.

- Partially-formed internal threads at the lower end of the insert cause it to expand during installation to mechanically lock it to the housing material.

The installation tool cold-forms these threads to cause the insert expansion to occur.

Installation Instructions:

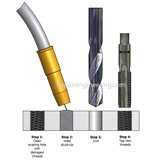

Installation Procedure:

- Drill out the old threads using the drill supplied in the repair kit.

- Counterbore the hole using the tool supplied in the kit. The tool has a built-in depth-stop feature that limits the counterbore to the proper depth for installation of the insert.

- Tap the insert installation threads using the STI tap supplied in the kit.

After the hole is drilled, counterbored, and tapped... clean the hole so that it is free of chips in preparation for installation of the insert.

- Install the insert using the installation tool.

- Apply oil to the insert driver to help lubricate it and to minimize the chance of galling the threads of the insert during installation.

- Screw the insert onto the installation tool by hand. The insert will only thread on part-way because of the partially-formed threads at the lower end of the insert.

- Thread the insert / installation tool driver into the prepared threaded hole. The insert should thread in easily until its flange contacts the surface of the counterbore.

- Using a tap handle, rotate the installation tool driver to thread it into the insert. The tap handle will be more difficult to turn as it expands the partially-formed threads at the lower end of the insert. Continue turning until the tap handle loosens-up and becomes easier to turn.

- Once the insert is seated, reverse rotation of the tap handle to remove the installation tool driver from the installed Time-Sert.

Questions and Answers:

Why does the installation of a Time-Sert require the use of an STI tap? What is an STI tap? Can a standard tap be used instead?

Time-Sert achieves its thin-walled cross-section due to synchronized internal and external threads of the insert.

The internal threads of the insert are designed to be used with standard sizes of fasteners. In order for the threads to be synchronized, the external threads of the insert are designed with the same pitch (spacing between threads) as its internal threads.

Because the external thread diameter and pitch is determined by the dimensions of the internal thread of the insert, the resulting external thread does not correspond with a standard tap size.

A "Screw Thread Insert Tap" (also known as an STI Tap) is designed specifically to be used in the installation of some types of thread inserts, including Time-Serts. An STI tap is different than a standard fastener thread tap; they can not be used interchangeably.

To illustrate the difference between a standard tap and an STI tap...

A standard tap used to create threads for a 1/2" NF fastener has a major diameter of .500" with a pitch of 20 threads per inch.

The corresponding STI tap for that particular insert has the same thread pitch of 20 threads per inch, but has a larger major diameter. (In this example, the STI tap major diameter measures .568".)

Return to Time-Sert Top

Impeller

Repair Project

Impeller Repair

Impeller Repair